Page 57 - Energize September 2021 HR

P. 57

TECHNICAL

in the motor remains relatively constant over the whole flow range. For example, when the flow rate is 140% of one pump’s capacity it

In VSD control, the operating point follows the system curve, which is may be more efficient to run two pumps at 70% than one at 100%

is optimal for pump efficiency. In general, the energy consumption and the other at 40%. n

drops dramatically when speed is reduced and the energy savings

with VSD control are significant. References

1. T Covary: “Focussing on energy efficient electric motors”,

Parallel connection of VFD pumps Energize 30 July 2021

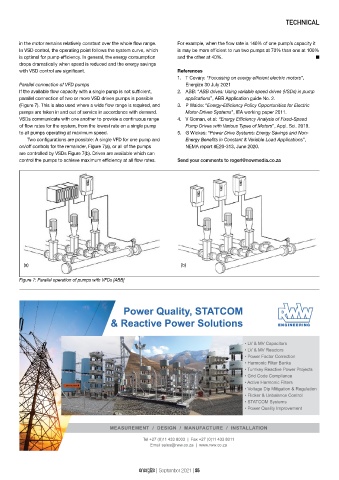

If the available flow capacity with a single pump is not sufficient, 2. ABB: “ABB drives: Using variable speed drives (VSDs) in pump

parallel connection of two or more VSD driven pumps is possible applications”, ABB Application guide No. 2.

(Figure 7). This is also used where a wide flow range is required, and 3. P Waide: “Energy-Efficiency Policy Opportunities for Electric

pumps are taken in and out of service in accordance with demand. Motor-Driven Systems”, IEA working paper 2011.

VSDs communicate with one another to provide a continuous range 4. V Goman, et al: “Energy Efficiency Analysis of Fixed-Speed

of flow rates for the system, from the lowest rate on a single pump Pump Drives with Various Types of Motors”, Appl. Sci. 2019.

to all pumps operating at maximum speed. 5. G Wickes: “Power Drive Systems: Energy Savings and Non-

Two configurations are possible: A single VFD for one pump and Energy Benefits in Constant & Variable Load Applications”,

on/off controls for the remainder, Figure 7(a), or all of the pumps NEMA report #E20-313, June 2020.

are controlled by VSDs Figure 7(b). Drives are available which can

control the pumps to achieve maximum efficiency at all flow rates. Send your comments to rogerl@nowmedia.co.za

(a) (b)

Figure 7: Parallel operation of pumps with VFDs [ABB]

energize | September 2021 | 55